Frequently asked questions

Do you have questions about our products? We’ve got the answers. Perhaps you will already find the solution to your question in the following.

Additionally, our photonic expert sales team will be happy to advise you on all topics related to CryLaS GmbH lasers. Contact us by e-mail at sales@crylas.de, by phone at +49-30-5304-2400 or via our contact form. We support you, starting from the technical basics to finding the ideal solution for your requirements.

The operation of lasers is possible pulsed or continuous, depending on the type. Instead of “continuous wave”, the abbreviation CW is also common here. For CW, one primarily specifies the power of the radiation as a parameter. Pulsed lasers have other characteristic parameters (pulse energy, pulse duration, frequency) from which the average power and the peak or pulse power can be calculated.

A Q-switch can increase the peak power of a laser by shortening the emission time. The Q-switch allows the laser to oscillate when the maximum population inversion is reached during the pumping process. This leads to an increase of the pulse power of the laser, as long as the pumping time is smaller than the lifetime of the upper laser level

Active Q-switching is based on electronic control. In passive Q-switching, the resonator is extended by a saturable absorber. Here, the transmission depends on the radiation intensity. Specifically, this means that as the intensity increases, more and more electrons are pumped to a higher state. A so-called giant pulse builds up and the saturable absorber becomes saturated at maximum occupancy inversion – it becomes transparent and the laser beam is released. This means that the release of the laser beam can be performed actively when the Q-switch is active. With passive Q-switching, the release of a laser pulse can vary in time, resulting in low pulse-to-pulse jitter. The advantage here, however, is that much shorter pulses can be generated.

Photocontamination or solarization means the reduction of the transmission of glass or similar due to the effect of UV radiation. The material discolors and thus prevents the transmission of a wide range of wavelengths. Solarization on optical fibers or other optical components sometimes leads to unusability. In the case of our lasers, this is particularly relevant for the wavelengths 213 nm, 266 nm and also 355 nm, which are found in the deep UV and are therefore particularly aggressive. One of our core competences is to prepare our lasers accordingly in order to avoid solarization as best as possible or to correct it with little effort – which unfortunately does not exclude a regularly necessary service by CryLaS.

These are characteristic parameters for pulsed lasers. The pulse energy can be measured and is in the µJ range for CryLaS lasers. The peak or pulse power is calculated from the pulse energy divided by the FWHM (full width half maximum) of the pulse (time). This is about 1 ns for our passively Q-switched lasers. The average power of the lasers can also be calculated. Here you multiply the pulse energy by the repetition rate.

CryLaS lasers can be precisely matched to your application. It is possible to attenuate the lasers by a stepless attenuator, to couple them in fibers, to output a time synchronization signal for triggering further components of your application or to provide the laser with an electrically controlled beam blocker. For frequency-converted wavelengths, a wavelength switch can also be used to emit the next lower frequency multiple of the fundamental (e.g. 266 nm / 532 nm, 355 nm / 532 nm, or 532 nm / 1064 nm). Beam expansion of up to 20 times is also possible.

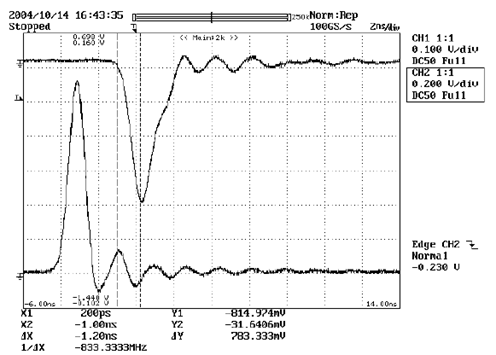

Since the Q-switching of our lasers is not electronically controlled, there is no standard information about when an actual laser pulse is generated. This must be actively measured, accordingly processed and put out. This is possible with our synchronization module. This is based on a small, fast photodiode and a deflecting optic. A small amount of the laser beam is directed to the diode and measured there (rise time < 2 ns). The electrical signal can be taken from an SMC interface. According to your wishes, you can choose between positive and negative polarity of the signal.

Figure 1: Laser pulse measured with synchronization module in positive and negative polarity

The attenuator can be used to operate the pulsed lasers from 100% to 3% of nominal power. It is based on polarization plates that enhance or degrade the transmission of certain polarization directions. The manual attenuator is operated by hand. By turning a wheel, the laser energy can be changed at any time. The electric version can be connected to the PC via USB and is operated with the supplied software. The mode of operation is the same, but here the advantage is that a direct percentage value for the laser energy is set and automatically approached.

It is possible to couple our pulsed lasers into LMA (large mode area) optical fibers. For this purpose, there is a corresponding adapter on the laser aperture to which an SMA fiber is screwed and appropriately adjusted by CryLaS engineers. Our fiber coupling suits SMA fibers with diameters of 100 µm, 200 µm, 400 µm and 600 µm. Coupling efficiencies of up to 80 % can be achieved. It is also possible to purchase the fibers through CryLaS. The special feature of these optical fibers is the free-standing fiber end, which prevents the fiber cladding from being damaged by too much irradiated laser power. The advantage of fiber coupling is the flexibility that can be achieved. It is possible to direct a laser beam to hard-to-reach cavities or similar. A disadvantage is the extensive loss of beam quality after decoupling from the fiber. Fiber coupling is available for our 355 nm, 532 nm and 1064 nm pulsed lasers. For lasers with lower power, 266 nm can also be coupled. However, you have to expect solarization effects here.

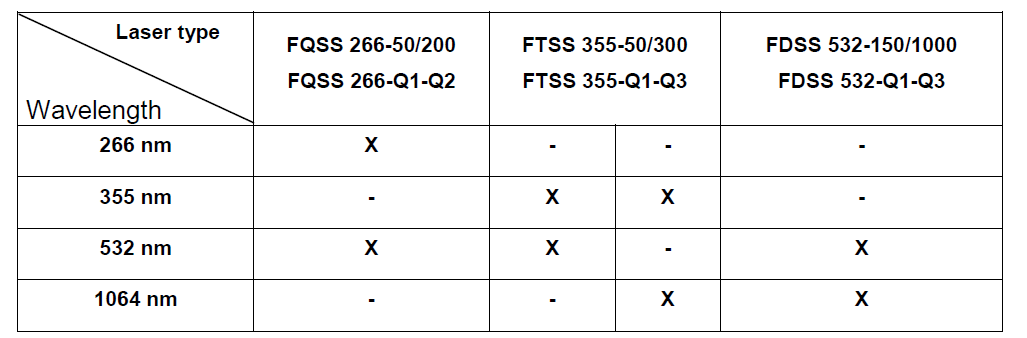

The output radiation of our lasers can be switched back and forth between two different output wavelengths, due to the previous frequency conversion. The options depend on the type of laser.

Figure 2: Possibilities for using the wavelength switch (Possible wavelengths per laser type)

The wavelength switch is a mechanical component in front of the aperture of the laser, which contains two optical filters. It is possible to install a manual or electric switch. With some lasers, it is also possible to optimize the respective active wavelength with respect to its beam profile by influencing the laser head temperature.

The attenuator is based on polarization plates that behave differently for different wavelengths. Therefore, it’s not possible to combine these two options.

Our pulsed lasers are triggered internally or externally. The internal triggering runs either via the supplied software, or on a default value set at the factory. Our software makes it possible to trigger the lasers from 1 Hz to the defined maximum. With an external trigger, i.e. a TTL signal supplied via the Sub-D interface, the laser can be triggered at < 1 Hz. It is not possible to exceed the maximum frequency. Our lasers are optimized to a frequency at which they run according to specifications. If the frequency is changed, the beam parameters may change and, for example, the pulse energy may vary.

There are two ways to block the radiation of an active laser at the aperture: A manually moved mechanical shutter and an electrically controlled beam blocker. The latter, unlike the former, is not intended as a safety feature, but rather to gate the laser beam.

The FQCW-C series is a comparatively new development of our company. It functions on the basis of the FQCW266-10 and FQCW266-25 lasers. C is short for “compact”, which means less material is required and therefore costs are saved. The beam properties of the C models are hardly inferior to the standard models and, like the entire FQCW266 series, convince with a large coherence length, low spectral width and single-frequency operation.

We will find the right solution.

Let our photonics expert sales team advise you about solutions to your requirements.

All of our departments are staffed by experts in their fields. We will be glad to advise you on your application, inform you about our products and take all important variables into account to find the best possible solution.