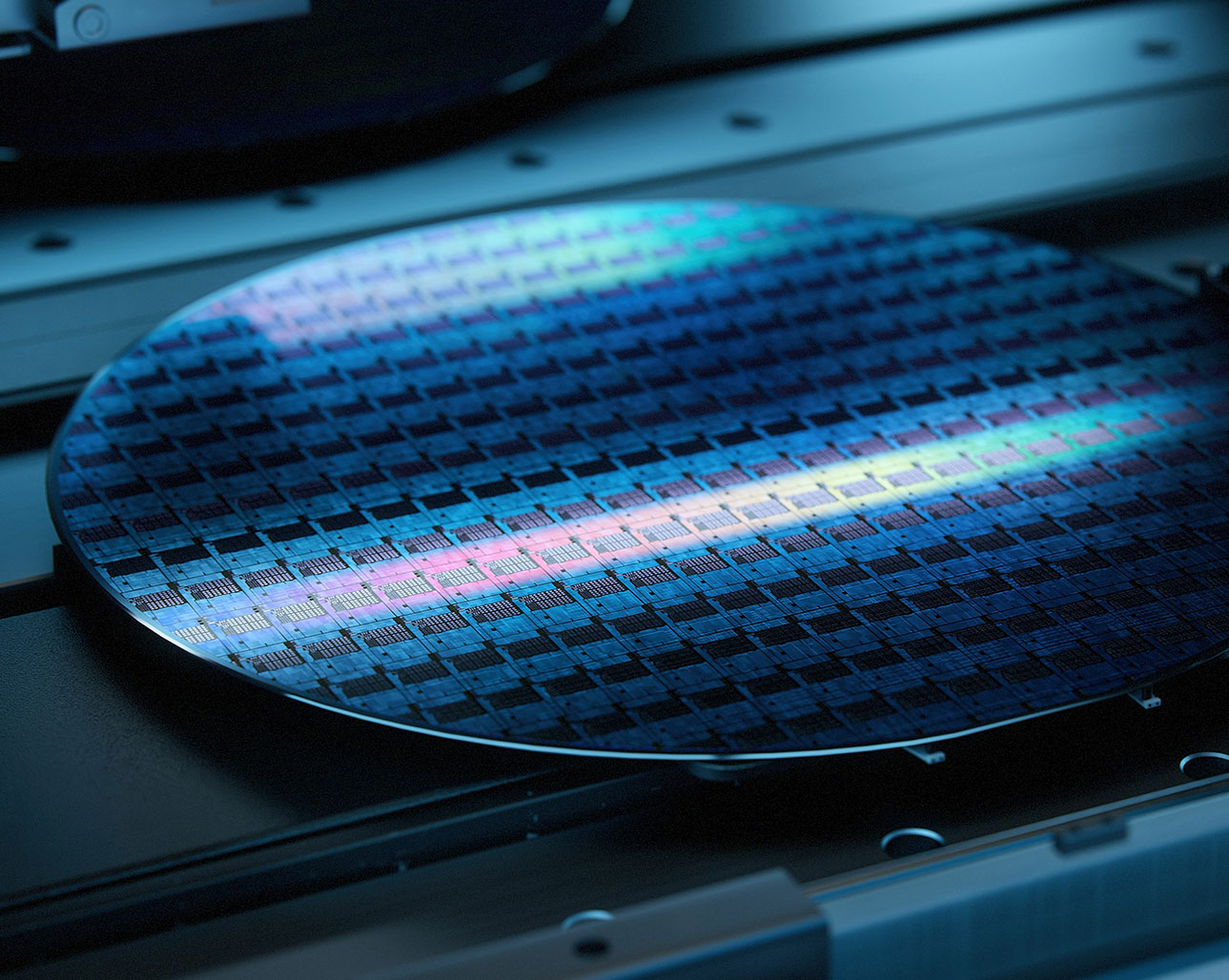

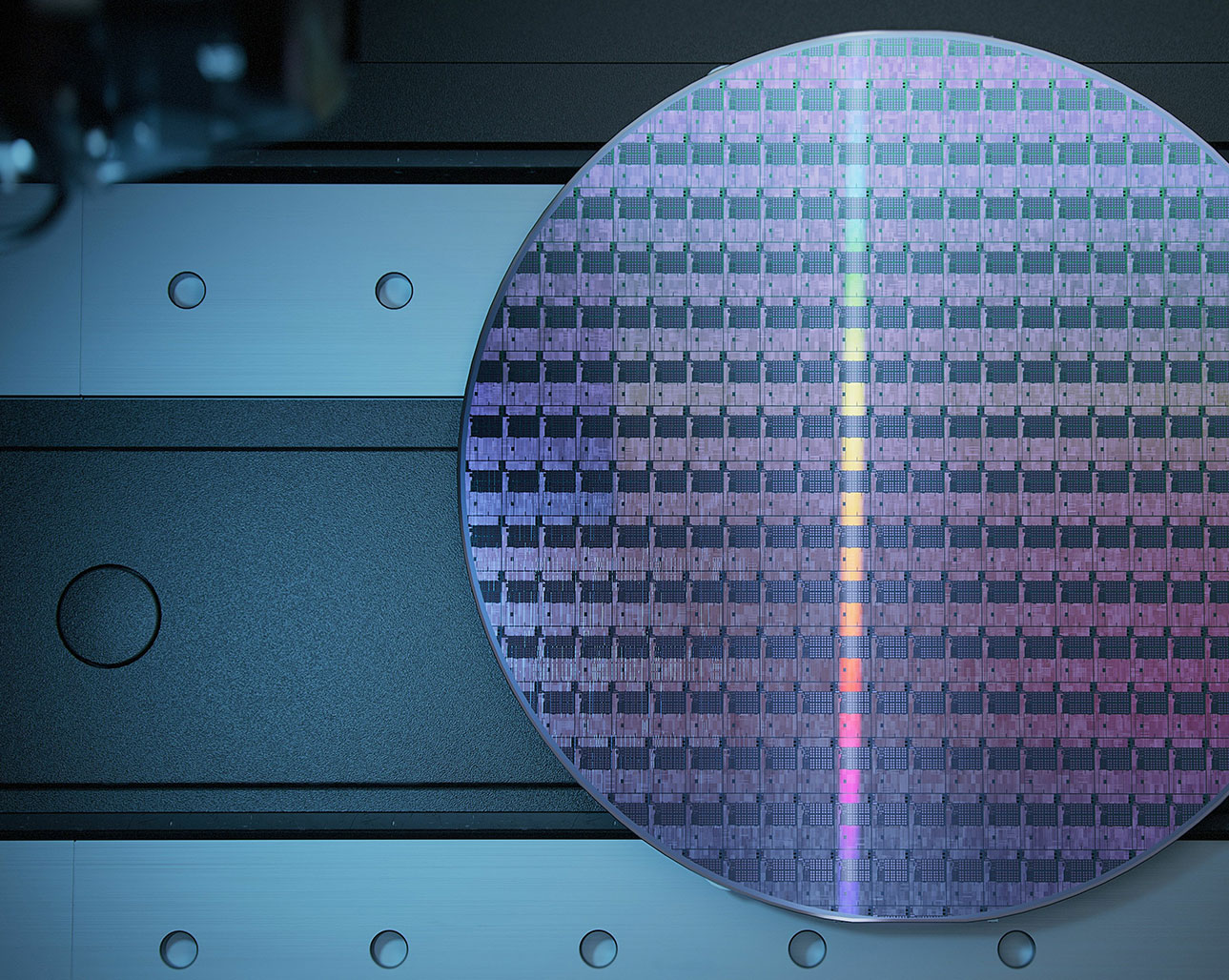

Wafer Inspection

Detection of roughness, defects and particles

Based on scatterometry, silicon wafers in the semiconductor industry are quality inspected using laser technology. Specifically, this involves the detection of roughness, defects and particles. Due to the constantly advancing development and especially miniaturization of semiconductor devices, the tolerance for defects in wafers is getting smaller and smaller.

Near zero tolerance has developed with respect to particle contamination, crystal defects, and other known defect types. In addition, there are new types of defects that bring new problems in wafer fabrication. To improve the production yield of compound semiconductors and silicon devices, the study of the wafer surface, non-surface layers and bulk crystal plays an increasingly important role. In addition to analysis by laser radiation, technologies such as electron or X-ray scattering are common.

Detection of laser light after elastic scattering from surfaces

The detection of laser light after elastic scattering on surfaces has several advantages: a small minimum detectable size of defects and particles, a high throughput due to high power, good resolution due to low wavelength and process speed during inline analysis. Laser-based wafer inspection enables high sensitivity and high throughput on the wafer surface before actual patterning.

Relevant influences, such as non-uniformities, defects, particles and scratches, flatness, irregularities in the structure of the crystals or the uniformity of the doping can be determined and improved with laser-based and interferometric applications.

Continuous wave operation with single-frequency DPSS UV lasers

Single-frequency DPSS UV lasers in continuous wave mode are of great advantage in the semiconductor industry because they can provide precise interference patterns and have low intensity noise. In combination with a narrow linewidth, an excellent SNR (signal-to-noise ratio) is present, resulting in high measurement sensitivity. Absolute wavelength stability and long coherence length are also beneficial for accuracy during long-term measurements. The ability of our CW-DPSS lasers to produce excellent beam quality with high power and minimal footprint allows maximum flexibility in use and operation.

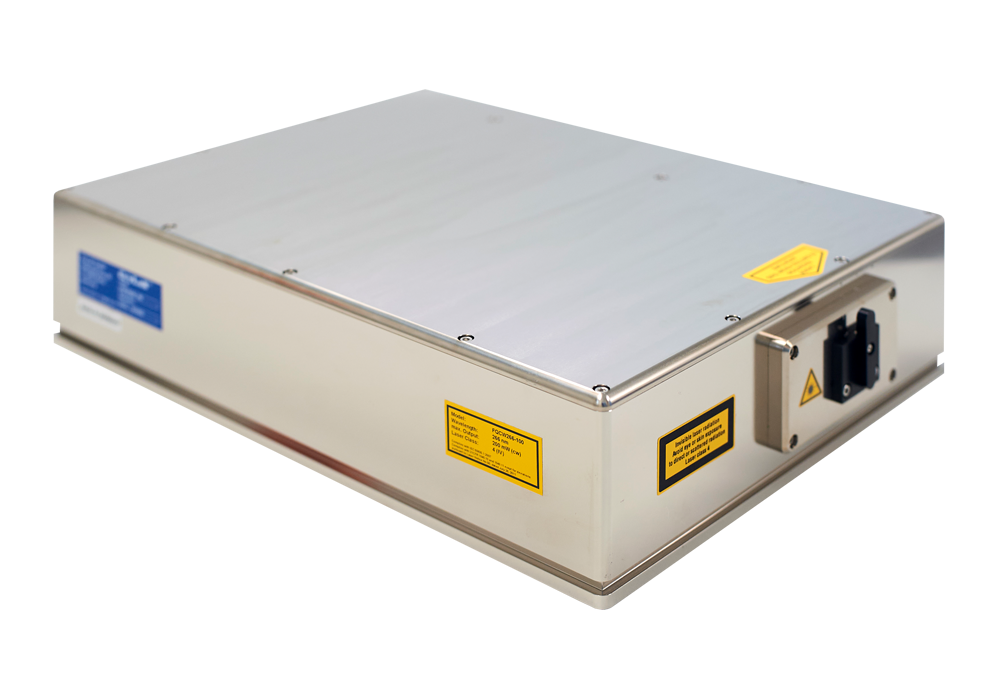

Related products:

FQCW266-50

- Power: 50 mW

- Linewidth: < 300 kHz

- Coherence length: > 1000 m

- Beam quaility M2: < 1.3

- Fundamental mode: TEM00

FQCW266-100

- Power: 100 mW

- Linewidth: < 300 kHz

- Coherence length: > 1000 m

- Beam quaility M2: < 1.3

- Fundamental mode: TEM00

FQCW266-200

- Power: 200 mW

- Linewidth: < 300 kHz

- Coherence length: > 1000 m

- Beam quaility M2: < 1.3

- Fundamental mode: TEM00

FQCW266-300

- Power: 300 mW

- Linewidth: < 300 kHz

- Coherence length: > 1000 m

- Beam quaility M2: < 1.3

- Fundamental mode: TEM00

FQCW266-500

- Power: 500 mW

- Linewidth: < 300 kHz

- Coherence length: > 1000 m

- Beam quaility M2: < 1.3

- Fundamental mode: TEM00

FQCW266-1000

- Power: 1000 mW

- Linewidth: < 300 kHz

- Coherence length: > 1000 m

- Beam quaility M2: < 1.3

- Fundamental mode: TEM00